Using 3D design software, we’ll take your product concept from initial design consultation through design and moulding to the manufacture of your final GRP product.

Design

Micris Limited will take your product concept from initial design consultation through design and moulding to the manufacture of your final product, designing, producing and commissioning your GRP project, from radomes to fire safety cabinets and bespoke projects.

Our design and drawing service uses CAD software, which enables customers to view their products before the design is finalised. CAD drawings can be used to assist with tendering processes etc.

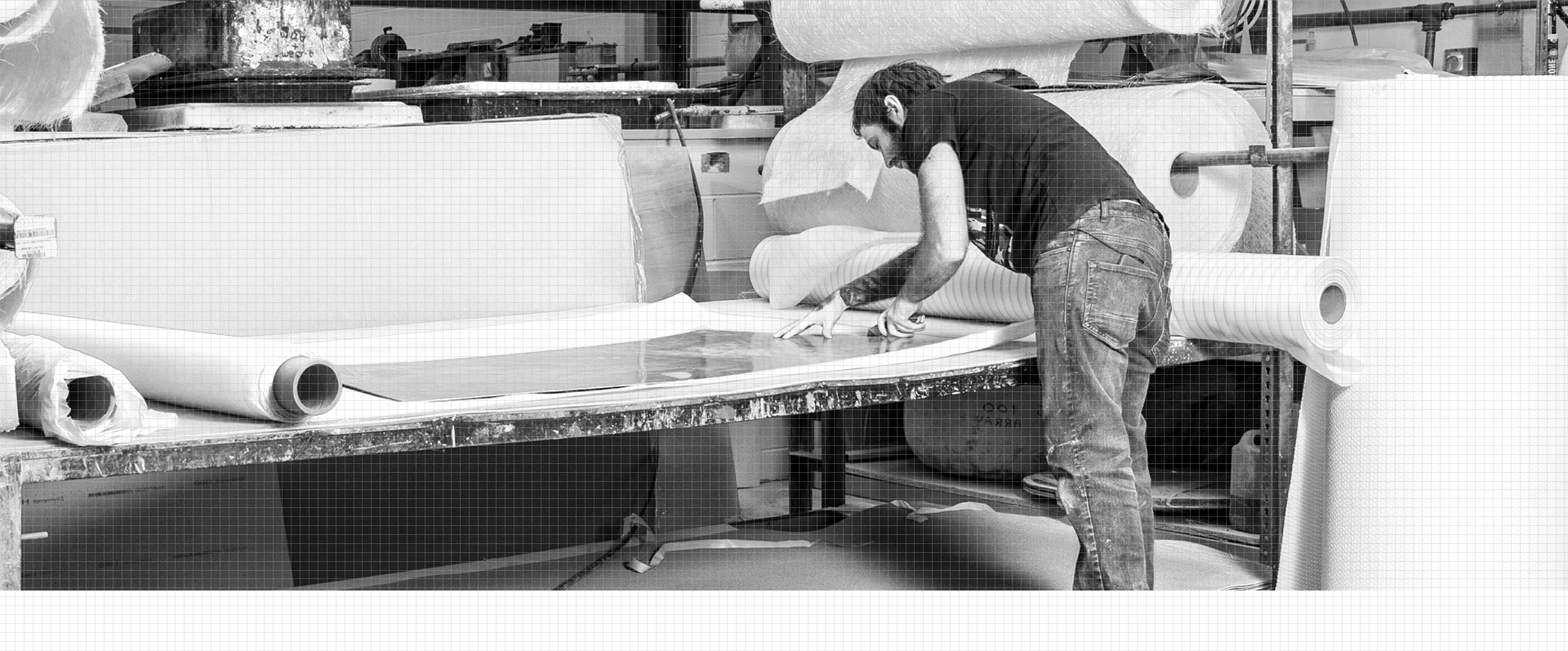

Pattern Making & Production Tooling

We will take your final design into a GRP component. We produce our patterns and production tooling to exacting standards, providing pre-production samples for final evaluation.

CNC Machining

CNC machining enables us to produce accurate and high-quality master patterns directly from designers’ CAD data, which we create the mould for your GRP product.

Production

We provide many GRP composite manufacturing production processes including:

- Traditional hand-lay

- Vacuum infusion

- Light resin transfer moulding (RTM)

- Pre Preg