Brief

Micris spoke with a company based in the Netherlands. They had a requirement for a radome that could house a portable satellite communication system that operates over the Ka frequency band. In short, the main requirements were:

- Portability – panels need packing into cases and lightweight;

- Quick assembly;

- Watertight to IP65;

- Frequency performance over the Ka band to be <-0.75 Db;

- UV stable exterior finish.

About Our Approach

We have never been part of the design of a portable radome. Therefore, we look into the radome market to see if there was already any innovative designs we could base this radome on. But from our research, we did not find any that appear to suit this requirement. We decide to have meetings with both the client who was our customer, but we also sought to include the end customer. Accordingly, we could fully understand how this radome needs deploying and the environment it was going to exist within.

From the meetings, we were able to start and put together some design intents. That way, the team could review and come up with the optimum panel size and weight to meet the necessary build time.

We also had to take into account some further requirements that came out of the meetings. First, the radome needs to have an access hatch that could allow components of the radome’s system to remove and/or replace. Moreover, this also needs to be a quick-release type of system, but also very robust. Some of the panels need to have air ducts built into them, as in some situations. Some felt that air conditioning units would also be necessary for certain situations.

All the above was very different from the radome Micris currently manufactures, not to mention other manufacturers. Accordingly, by using a new type of pre-preg composite system, we knew this was going to take a fresh look at current radome design.

Manufacturing

To allow the manufacture of this radome, firstly we need to choose the best materials to get the RF performance, structure stability and keep within the weight criteria.

After reviewing the various manufacturing processes and materials, we chose to start with an epoxy pre preg system. The reasons for this choice were as follows:

- Precise layer thickness could be achieved, which is critical for the frequency band;

- We can use an open cell core material which will aid in the weight saving;

- Good structural stability;

- A UV stable outer coating for application over the material.

Using software, we design the ply lay up to optimise the ply book and allow samples to be manufacture for testing. Then we look at A sandwich and C sandwich for the RF performance.

From these results, we decide to validate the 2mm and 3mm pre preg C sandwich options, as they gave the optimum RF performance with the structural integrity we required.

Testing & Manufacturing

We conduct all the RF testing at the University of Liverpool in the Electrical department head up by Dr Yi Huang.

We manufacture the necessary samples for testing and had the test conducted. The report is available for reference.

From the test reports, which in the main validate our predictive work, the C sandwich 2mm Nomex was chosen for the construction of the radome.

The next stage was to design the radome, considering the design criteria of the portability, and ease of construction. We also had to consider another factor due to the material decision. Namely, that the radome panels need manufacturing under vacuum. Then, they’ll need heating up to a temperature of 120 deg C.

Using our 3D CAD software, we produce and discuss various designs with the client, to ensure it met all the needs. We also had to validate that the end radome design could accommodate the system that the client uses.

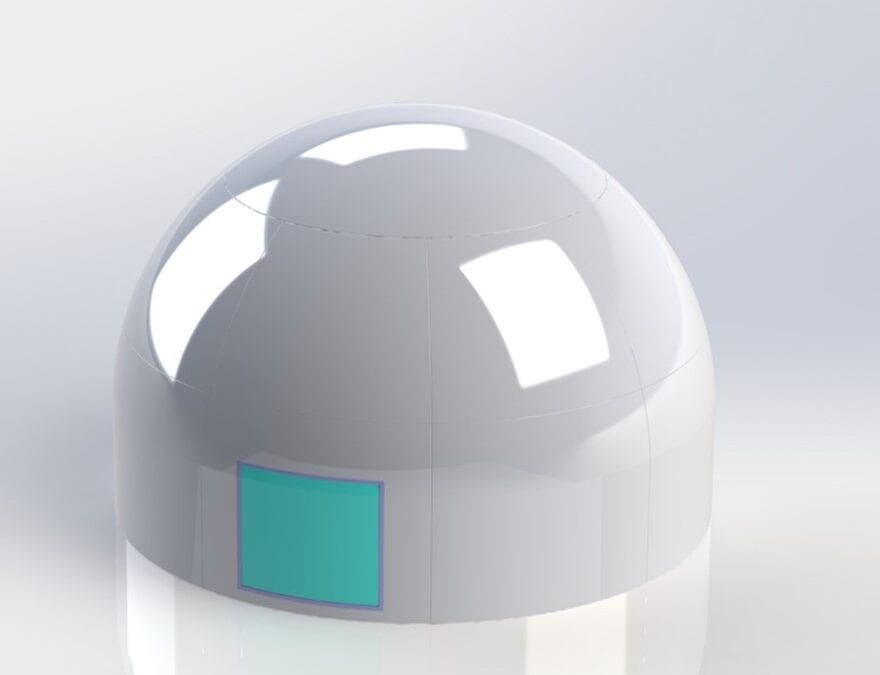

Below are some of the designs that were under consideration

This was an 8-petal design using a 3-tier configuration.

Mockup of the system for the inside of the radome. This is necessary to validate the necessary swept volume.#

Another idea in the designing stage.

Hatch Design

As the brief states, the hatch had to be a completely new design, which was easy to use. Moreover, it must be:

- large enough to allow the removal of parts from the system inside the radome, and;

- be very easy to open and close, also maintaining the water integrity.

A key area to the design of the hatch would be the closing mechanism. Previously, we would use a simple quick quarter-turn device. But it was felt that this would not be a robust solution for this application, so we had to research different types of available catches that were readily available. We discover that catches that would be the optimum of this application would ultimately not work with our usual hatch design. Moreover, we learn that this would also require a complete re-design

Below shows the final design including the catches that were chosen.

The final design that receives approval/ Plus, the client working drawings.

Tooling design

Once the design of the radome had been completed, the next stage was the tooling design.

This also presents a new problem, as we were using a product that requires manufacturing at temperature and under vacuum. The shape of the panels had undercuts, that would not allow the removal of the final product from the tooling without having removable flanges. This gave us the problem of having 2-part tooling that needs to be airtight on the joint line to allow the vacuum to form over the tooling using a bag.

We came up with the design for the cnc masters to have a 1-piece flange system that could accommodate a sealing system on the final tooling.

Micris uses a company to manufacture the CNC tooling, but we then complete the tooling design ourselves. Then, we submit all designs in a 3D format to the CNC company who validate the CAD data to ensure it will translate onto the CAM software.

Some pictures of the CNC masters by Micris.

From the CNC masters, production tooling is manufactured. This is done inhouse so we can control the quality and time scales. In short, we manufacture the tooling from a composite resin tooling system. We then design it for the processing temperature.

Below, some pictures of the composite tooling in manufacture.

Production

To allow the manufacture of this radome, and through the choice of materials, Micris needs to invest into additional equipment. In essence, the main requirement was a processing oven that was large enough. Plus, it needs the controls and safety requirements that would allow the oven to operate overnight. Therefore, we can use the downtime of the factory to process the materials and be ready for production in the morning.

The final design and type of oven was made after consultations with companies who had the relevant experience to advise us.

We install a 4m x 4m x 2.1m gas-fired oven. We also had to increase the gas supply into the works, as this was insufficient to both the oven and factory heating. Ultimately, the oven is programable to allow a wide range of materials we will use.

Below is a picture of the final radome.

Recent Comments